6.5. Evenness test

NOMOS movements are distinguished not only by their precision, but also by their exceptional thinness. This does not happen by chance. In addition to innovative designs and special material properties, the material properties of the parts, such as thinness and evenness, are also very important. In our movements, space for each component is limited. This means that the distance between neighboring parts is not very large. As a result, the wheels cannot move far up or down when turning—watchmakers say that they must turn with particular evenness. That is why, at NOMOS, each wheel is checked for evenness after the individual parts have been assembled: visually, using a camera system, and with extreme precision. This is the only way NOMOS can achieve perfect function in such a small space.

6.4. Pressing in the anchor shaft

The anchor shaft is a very short shaft with even shorter pins. Its dimensions and surface finish must be perfect. This is because the anchor plays a central role in the NOMOS swing system. It converts the rotational movement of the anchor wheel into a back-and-forth movement, which gives the balance wheel an impulse with every contact. This is actually just a small push. But it involves the transfer of force combined with acceleration, taking inertia into account. Friction also plays a major role. So everything has to be perfect! The anchor shaft, pressed in at just the right height, ensures that the anchor is perfectly positioned between the anchor wheel and the balance wheel. Rolled pivots reduce friction in the bearing, and particularly tight tolerances keep the anchor as straight as possible. So the anchor shaft, as tiny as it is, has a pivotal role to play in the overall accuracy of a mechanical watch.

6.3. Quality assurance: tactile measurement

A tactile measuring method registers the contact of a body with a measuring tip. In other words, they get up close and personal. Modern optical measuring methods are very fast and very accurate. However, this is not always enough when it comes to manufacturing watch movements. Due to a wide range of influences—such as light, surface texture and reflections—the measuring accuracy of optical methods decreases in some cases. This is where tactile processes have the advantage. Whether inner or outer diameter, heights or entire contours, manual or fully automatic, almost anything is possible—if you know how. Only qualified technicians like those at NOMOS Glashütte know how to use the various measurement methods correctly.

6.2. Adjusting the end of the balance spring

The last, curved part of the balance spring is known as the end curve. In the past, there was even an inner end curve. The end curve is used to attach it to the stud holder, and thus to the balance cock. In addition, the end curve is often used to quickly adjust the pace of the watch, because the frequency—which is the oscillation of the balance wheel—can be influenced by changing the effective length of the balance spring. To ensure that this happens reliably and in even steps, the end curve must have a perfect radius to the center point. This requires a keen eye, a steady hand, and a great deal of experience.

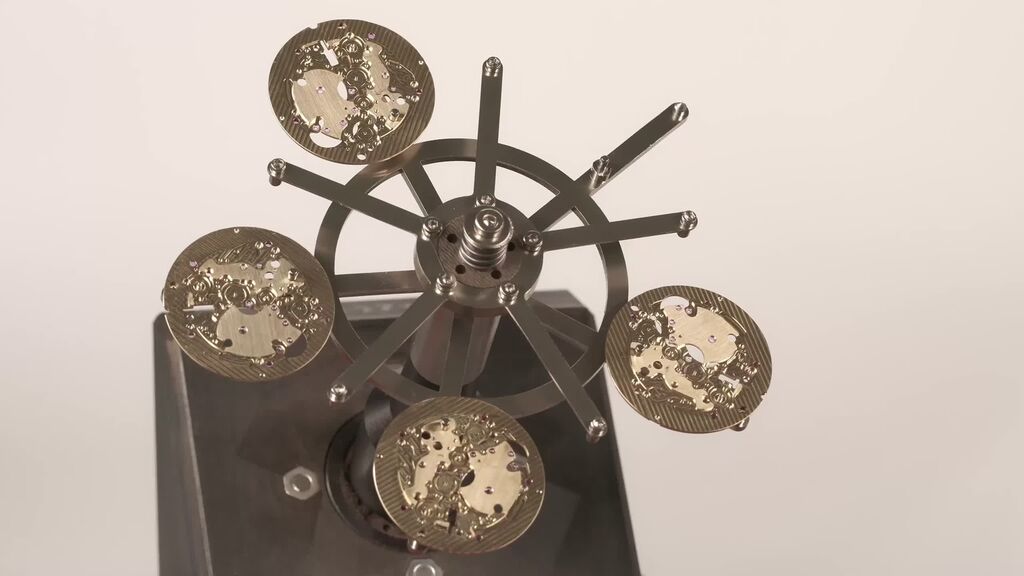

6.1. Sandblasting

Almost all of the framing movement parts at NOMOS are allowed to ride this carousel without having to queue: movement plates, three-quarter plates, balance cocks, and bridges. While they do, the parts also get a good sandblasting. But in a very gentle way—because it's not sand, but the finest bronze filings. This evens out the many different surface structures that result from the machining process. Not only does it look better, this also helps with optical measurement methods, creates an even surface for polishing, and smoothes some of the edges. And it's fascinating to watch!