Made in Glashütte: Work in portrait

"Made in Glashütte" is the title we give to the in-depth film sequences in which we portray the work processes in our manufactory. Individual steps that are important in the manufacturing of each watch are made clearly visible in these films from the perspective of our watchmakers. The calm and concentration with which the experts carry out a multitude of precise steps make the expertise and experience tangible—the very qualities that can be found in our watches. The first portraits of individual work steps from our manufactory have been received with great interest by watch enthusiasts. We are therefore happy to continue. The second season will start on January 1, 2023, and you can subscribe to it on the usual channels. You can find a compilation of the first season above.

1.12 Inserting chatons

The ruby set in gold—an aesthetic treat. In the past, this also had technical benefits: to perfectly define and maintain the spacing of the wheels. The ruby bearings for the wheel pivots were set, not pressed. A gold setting was ideal for this as the material is soft, allowing the stone to be set well. In addition, the stone in the polished chaton develops its “fire” when the red ruby is reflected in the hollow of the chaton. Inserting and screwing chatons in place requires a particularly steady hand. Watchmakers sometimes even hold their breath, because one slight wobble and the polishing starts all over again. Modern manufacturing accuracies no longer require setting. The stones can be pressed directly into the plates. But where does that leave the fire? This tradition and the perfect interplay of color and light, of cut and polish, live on in our finest watches.

1.11 Electrical discharge machining

Colloquially known as “spark machining”, a wire uses sparks to cut the smallest components with extreme accuracy from a disc. The machine can thread the wire into the work piece and then start cutting it out under water (ionized water or dielectric). What is great is that several discs can be machined simultaneously, thus producing several parts at once, something that is rather difficult with a fretsaw.

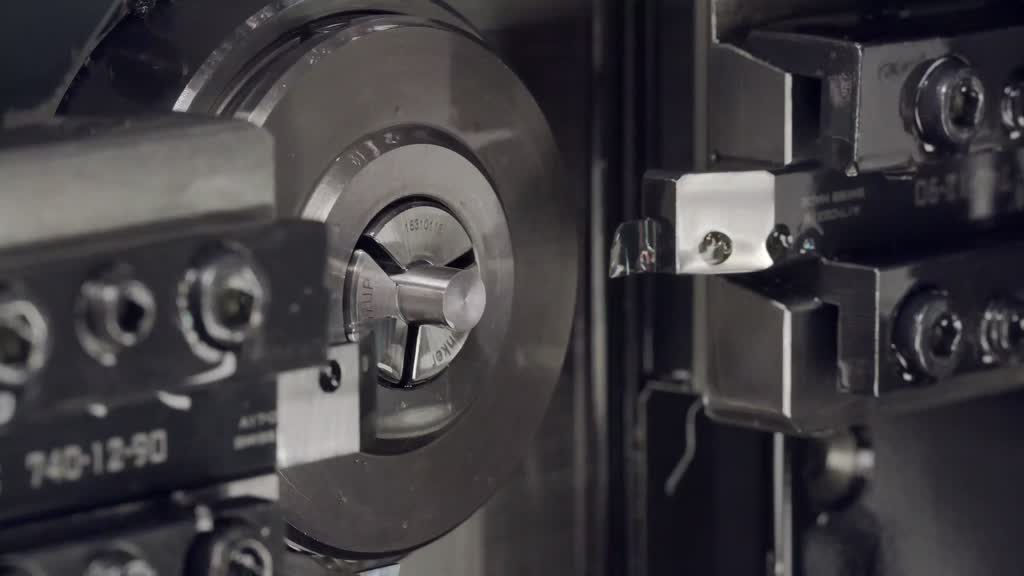

1.10 Turning the corrector wheel

Numerous operations are required to produce the corrector wheel. Turning, centering, drilling, countersinking, deburring… All possible on our CNC automatic lathe. But the machine only does what our programmers instruct it to do. And that involves numerous settings. Speed, travels, feed, the selection of the correct tool and the perfect amount and temperature of the cutting oil. And let’s not forget the toolmakers. After all, the quality is only this good because of the perfect work of the specialists behind the machines.

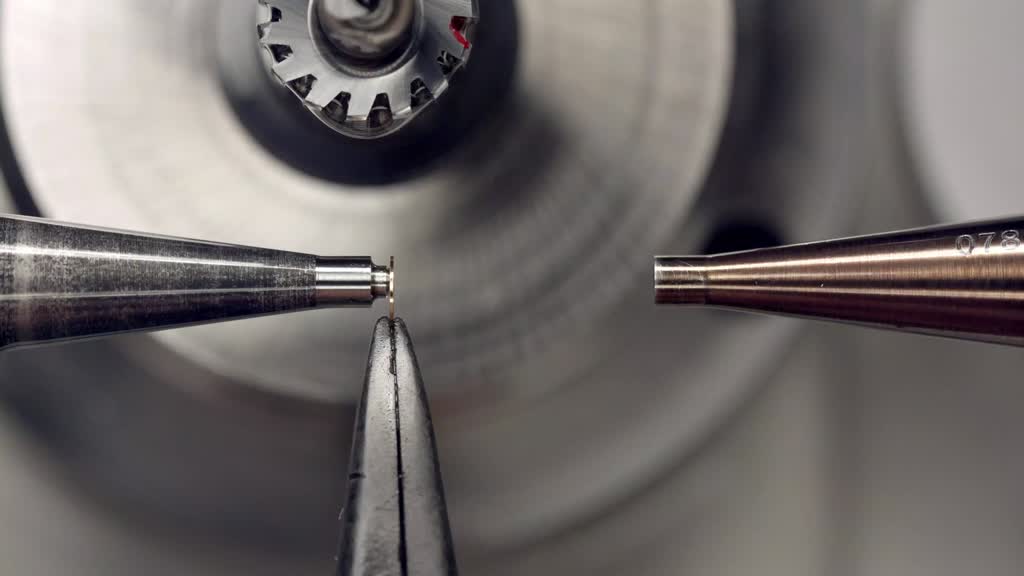

1.9 Bonding the escapement

Small pink beads of adhesive create a firm, low-tension bond between the balance and the balance bridge. To be more precise, the end of the balance spring is glued to the stud. Previously, the spring was pressed together with a pin in a hole, which led to tension and deformation. A lot of time was required to ensure a stable accuracy. The bonding technique provides a tension-free connection between the balance cock swing system and the balance bridge. The balance spring and balance cock can begin their work as the watch’s pacesetter immediately and with consistent precision. Each bead of adhesive has a diameter of 0.35mm and a volume of 0.025mm³, weighing 0.029mg. With a half-liter bottle of adhesive beads, we could bond over 15 million balance springs.

1.8 Grinding off the holding burr

Modern technology can do a lot—especially all at once! However, it still has its limits. The milling and electrical discharge machining of multiple parts from a blank requires the subsequent grinding off of the holding burr. If we didn’t do this, the parts would become dislodged from the blank, and who knows what route they would take through the machine. At any rate, such an excursion would be the death of any part. Thus, we prefer to grind off the holding burr, which holds the parts in place until the final machining step. With a lot of practice, this can be done very quickly and very precisely.

1.7 Measuring the milling depth

Consistent control from the first milling path to the last. Only if each step in the process is successful will the end result be a component that functions reliably. And here, checking is something that needs to be learned. The correct measurement technique is a requirement for feasible results. And if everything fits, this single milling path will later become a date lever cover.

1.6 Date assembly

The patented date mechanism in our DUW 6101 caliber. The key feature is the heart-shaped program disc that causes our pawl to advance the date only on every fourth revolution. No big 24-hour wheel. A constructive solution that requires little space and allows us to produce very flat movements. However, during assembly, careful attention must be paid to the correct positioning of the parts relative to each other. Only if we get this right will the next day roll around.

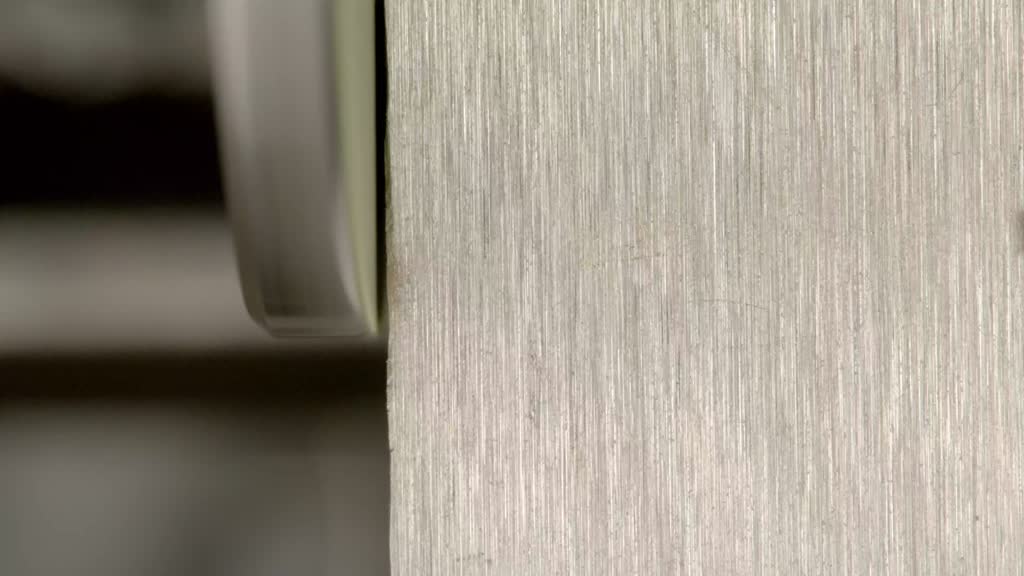

1.5 Grinding tools

There is no good result without good tools. In order to ensure good quality, we make the tools ourselves, which has many advantages: More creativity is allowed in our construction processes—we can create contours and shapes that are more difficult to realize with standardized tools. In manufacturing, we can fine-tune machining processes that meet our wishes and the properties of the material, which leads to higher quality and productivity. We are flexible and fast, and we gain more experience every day. As always in Glashütte, we are constantly optimizing what we do.

1.4 Milling round blanks

Measuring comes before milling. It is extremely important that the round blank has the correct thickness and the correct position in the machine. We’re talking about accuracy down to the mu (µ) after all. Every starting point, every movement of the milling machine, the chronology of the contours, planes and drilling holes … none of this is random, but rather precisely predefined, drawing on a great deal of experience. Many tools can be exchanged automatically to guarantee consistently high quality and efficiency. The rotation rate and forward speed of the milling machine are coordinated for optimal milling. Those who mill too fast will have to spend more time later deburring by hand. This can be avoided. Here quality saves time—and we like reducing things to the essentials! The milling of the round blanks sets the foundation for the precision of the watch.

1.3 Hobbing the accelerator wheel gears

The gear hobbing process guarantees that one tooth is like the other. Here, all teeth are made at the same time. Previously, each individual tooth space was milled one after the other in subprocesses. This ensured that the teeth gaps were all nice and the same, but not always so functional. However, the production of appropriate hobbing cutters, as well as the precise adjustment of the machine, is a particular challenge nowadays. With our hobbing specialists at NOMOS Glashütte, the teeth are not only the same, but also perfect!

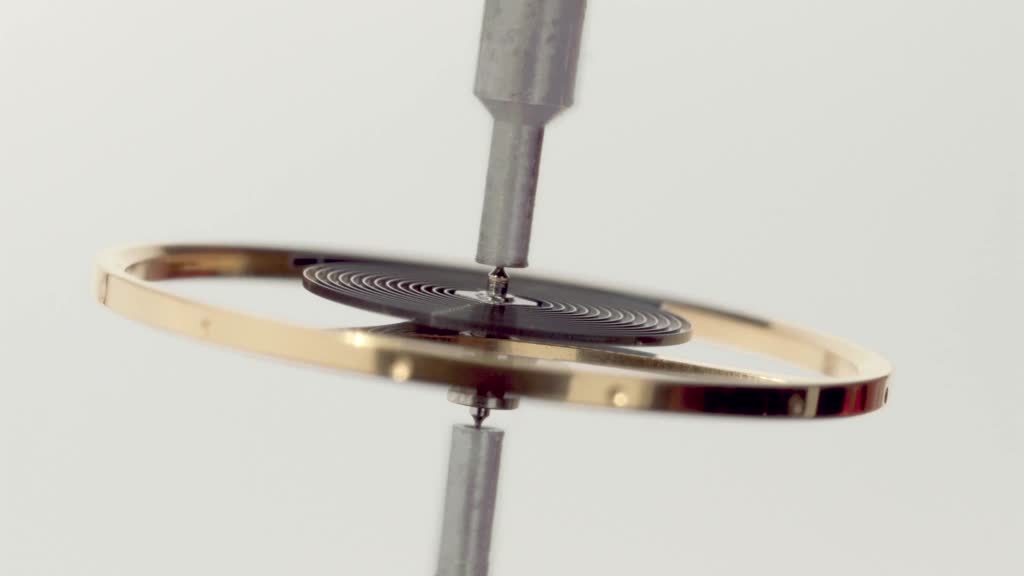

1.2 Adjusting the balance spring in the watch

Once our tempered blue NOMOS balance spring has been married with a selected balance bridge, it needs to be scrutinized again. A watchmaker checks that everything is running smoothly and evenly. If not, now is the time to act as it will be almost impossible to correct later. Only a small number of experts are able to identify and rectify these issues. Many weeks and months of training are required to be able to do this work. Our engineers have developed software for training purposes that trains the eye to recognize these defects. There is only room for a perfect balance spring in a NOMOS watch.

1.1 Glashütte sunburst

A very traditional decoration in a very traditional design. The Glashütte sunburst is unmistakable, today at NOMOS as it was in Ferdinand Adolph Lange’s time. There are many similar polishes. Carried out with the most varied tools. Sandpaper, cutters, steel brushes... but the radiance of the Glashütte sunburst can only be achieved with a grinding pencil and the appropriate grinding paste. What kind of pen? It’s a secret! What kind of grinding paste? That’s definitely a secret! Hundreds of tests were run to achieve a perfect grinding pattern and the recipe for the grinding paste was adjusted countless times. And here, too, it takes very experienced employees to let the sun shine on the wheel. A secret alone is not enough.