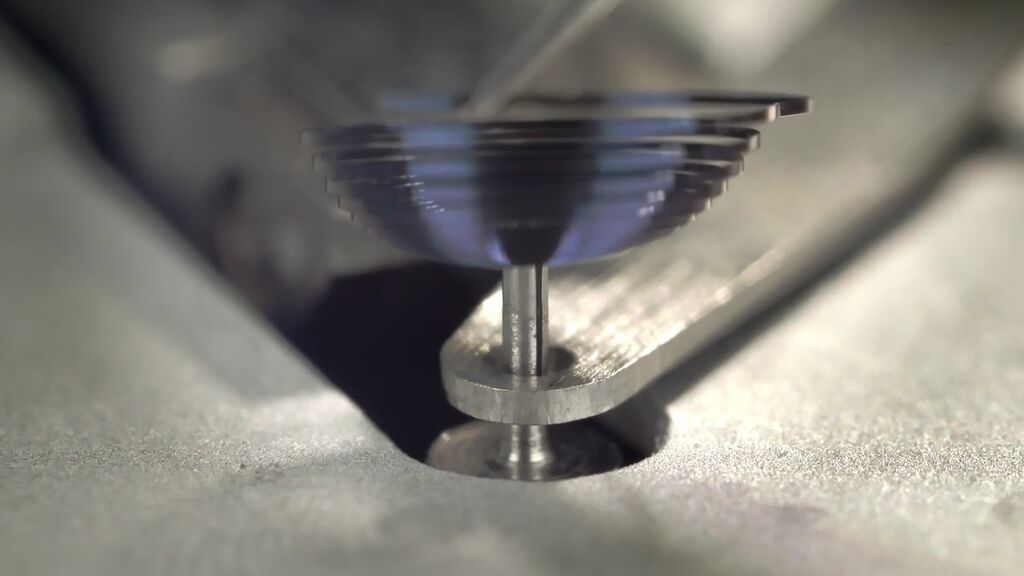

7.12. Pressing in the guard pin

The guard pin, as its name suggests, ensures proper interaction between the pallet and the balance wheel. The pallet imparts an impulse of force to the balance wheel, either to the right or to the left. This means that the impulse jewel on the balance wheel plate, receives a thrust and moves out of the pallet in the respective direction. The balance wheel now makes a half-oscillation, and the impulse jewel returns along the same path. It is now important that the pallet remains in the same position and can pick up the oscillating impulse in again. The guard pin prevents the pallet from changing sides unintentionally, which would immediately bring the watch to a standstill. A lot of responsibility for such a small part.

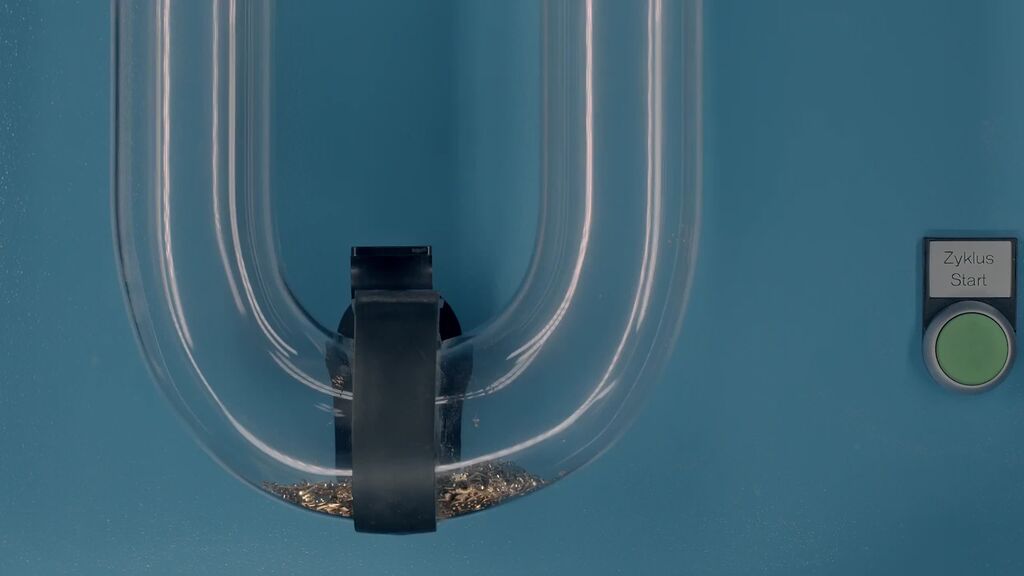

7.11. Automatic oiling

To ensure that everything runs smoothly, a mechanical movement needs the right amount of the right oil in the right places. Applying the specified type of oil to a selected point is not rocket science. It is only the quantity that is difficult to determine precisely and to apply consistently by hand. How much is exactly right, and how much is too much? Will my assessment be the same today as it will be tomorrow? And how will my colleagues assess the quantities? Automatic dosing provides a solution. Pressure and dosing time are determined in conjunction with the holding time so that the oil has time to drain off. A stable process, consistent quality. That's how things run smoothly.

7.10. Unclamping and dismantling the balance bridge

We should repeat this step as infrequently as possible. This is because there are risks involved every time the balance wheel and balance bridge are dismantled. If shaken too much, the balance spring can become slightly deformed. And correcting this requires a great deal of experience and an exceptionally steady hand. That is why we prepare the components in such a way that as little adjustment work as possible is necessary. Rubies and shock protection are pressed in with an accuracy of a few micrometers. This means there is a good chance that everything will fit right away. The less adjustment is required on the balance wheel and balance spring, the faster the movement will achieve stable accuracy. In this case, less is often more.

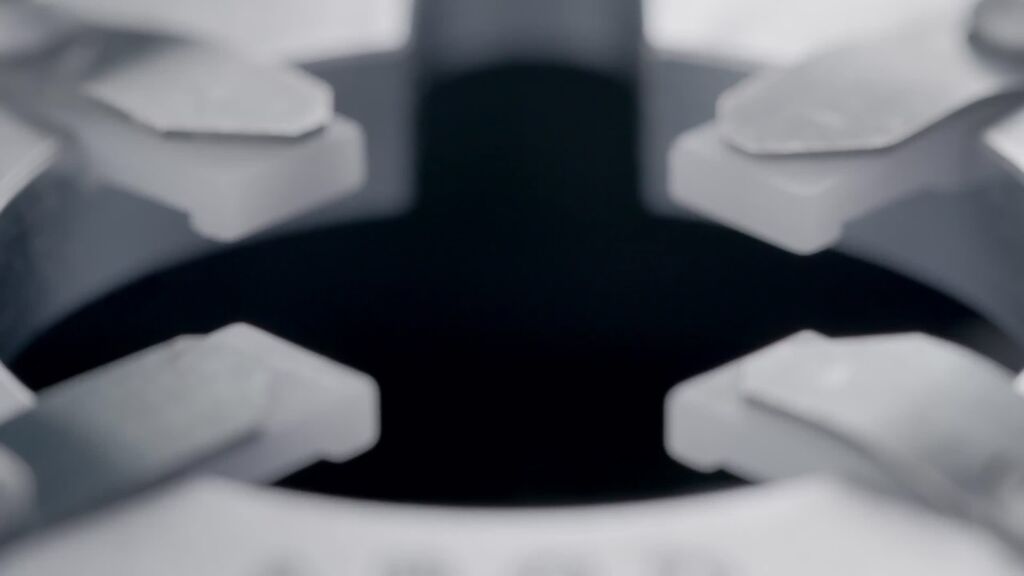

7.9. Hardness testing

The hardness of a material is important for many aspects of watchmaking. It influences the function of the component, how it wears down, and thus how long it can be used—as well as the friction between two components, the corrosion resistance, elasticity, and many other properties. Measuring hardness is a crucial aspect of quality assurance, not least because hardness cannot be assessed visually.

7.8. Cleaning the movement plates

Cleanliness is of utmost importance in the manufacture of watches and mechanical movements. Even the smallest dust particles can impair functionality or detract from the aesthetics of the dial. For this reason, movement parts undergo a variety of cleaning processes during the manufacturing process. Cleaning is particularly important before measurement and testing. Otherwise, the results could be severely distorted. This film shows how movement plates, after being fitted with rubies and pins and having the perlage applied, are thoroughly washed and rinsed several times. This also removes any oil and grease residues. The next step, electroplating, then seals the decorated brass surface. This is the only way to ensure that everything remains beautiful for a long time.

7.7. Pre-assembly of the balance bridge

The balance bridge is pre-assembled with the regulation system, which consists of the stud support and regulator, as well as the shock protection. The stud support holds the spring stud, which will later be glued to the end of the balance spring. The regulator with its regulator key allows for a quick adjustment of the rate. And the shock protection ensures that the thin balance pivots are protected, even when things get really bumpy. All these individual parts and components create the ideal conditions for the balance to oscillate evenly at the correct frequency, while also providing optimum protection.

7.6. Visual inspection of Tangente Update

Visual inspections take place before, during, and after watch assembly. Everyone wants their watch to be precise and perfectly beautiful. Numerous steps are necessary to ensure that Tangente neomatik Update shines in all its glory—by being technically and aesthetically flawless, right down to the last step. Care and patience are required to carry out the final inspection of a watch; quality control requires a skillful eye for the perfect interplay of parts and the purity of surfaces, structures, and colors. It is a task with a great deal of responsibility, and very enjoyable too. Especially when it comes to NOMOS watches.

7.5. Classifying the balance spring and balance wheel

For a mechanical watch to keep accurate time, the balance—consisting of the balance wheel and balance spring—must oscillate at a precise frequency. The elasticity of the spring and the moment of inertia of the balance wheel are decisive factors here. Both values together determine the frequency. But which balance spring fits with which balance wheel? At NOMOS Glashütte, exact measurements are taken. These measurements are then used to decide which balance springs and balance wheels should be paired up. Other couples at NOMOS Glashütte meet more organically—the head of the NOMOS research department and his wife, for example. There are some things in life that simply cannot be measured!

7.4. Separating turned parts

Minute wheels in the wind tunnel! Our minute wheels are first produced as blanks without teeth in automatic lathes. After being cut from the raw material, the parts are rinsed clean of cutting oil, which also serves as a coolant, which then collected in a container. Despite sieving and subsequent cleaning, some very small chips stubbornly remain in the batch of blanks. These are now separated from the required parts in a kind of wind tunnel. With a shaking motion and a wind force that only allows small chips to fly away, the blanks remain behind due to their size and mass. Anything superfluous is simply blown away.

7.3. Measuring vertical play

In addition to lateral play, the vertical play of the wheels is essential for smooth, friction-free running. This means that the wheels must not jam in the bearing stones or between the plates. They must always be able to lift slightly before they touch the upper plate. This is the vertical play. Our qualified watchmakers are able to assess this play expertly with a magnifying glass. NOMOS movements are particularly thin, which is why the vertical play is also very tightly controlled. In some places, it may only be between 15 and 30 micrometers. This is very demanding from a purely visual point of view. Opinions tend to differ here. And before a decision is made based on different opinions, our automatic vertical play testing system has already measured numerous movements. This is done very quickly. When it comes to functionality, we prefer to rely on verifiable data.

7.2. Inspecting the Club Sport bracelet

This bracelet combines sportiness and durability with beauty. Functionality is a prerequisite. Various tests are carried out, including a visual inspection. The interplay between the polished and ground surfaces is fluid and dynamic. Visual inspection of the edges and surfaces, as well as ensuring that the bracelet fits to the case correctly, are necessary checks and measurements. After all, the bracelet is intended to hold a NOMOS watch.

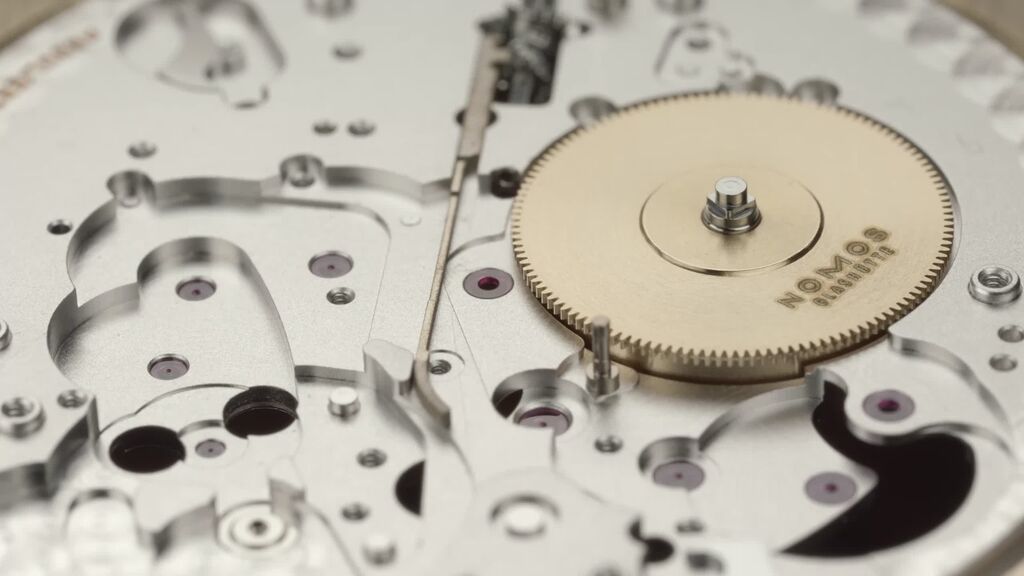

7.1. Assembling the gear train

The gear train: an umbrella term for numerous interlocking wheels. The DUW 3001 caliber provides an example of a running gear that transfers the power of the mainspring from the barrel—via the center wheel, third wheel, and second wheel—to the escape wheel. Another example is the automatic running gear, which uses the motions of the rotor to wind the mainspring. The number of turns of the individual wheels is progressively increased from the mainspring barrel to the escape wheel. After the first revolution of the barrel, the escape wheel has already rotated approximately 4,000 times. The automatic running gear works in exactly the opposite way. Here, the numerous motions of the rotor are converted into ever slower rotations. And everything happens under the Glashütte three-quarter plate, all on a single level. A thin and elegant design, which is a distinguishing feature of NOMOS watches.

Precision in every detail

Quality is not something that is achieved by chance—but rather by methodical measuring, adjusting, fixing, checking, and testing, until everything sits just right and works as it should. Above all, it is the result of upholding the highest standards. To ensure that our mechanical timepieces meet these standards, precision is a priority in every work step. From the perfectly smooth surface of the baseplate to the careful assembly and adjustment of individual caliber components, right up to the selection of the most suitable strap; expertise and the correct production methods are combined with a clear vision to yield the best results. This collection of artistic short films introduces you to some of the many processes that go into creating a high precision timepiece from NOMOS Glashütte.

6.12. Encasing the movement

The movement, including the dial and hands, is on its final stage before reaching its destination—the case. The long journey of manufacturing and assembling a NOMOS watch is finally coming to an end; the movement is being encased. The precise mechanics, which have been assembled and adjusted in many hours of manual work, are now protected in the case, completing the design of this small masterpiece of craftmanship. The case, dial, and hands are combined to match the character of the respective NOMOS model. The sapphire crystal glass back provides a breathtaking view of the microcosm inside. But the final step still involves many stages. A final inspection lasting several days is dedicated to checking the accuracy, appearance, rate, water resistance, and numerous other aspects of the watch. Like a final exam, it is always exciting—and always gratifying when a watch passes with flying colors.

6.11. Pre-assembly of the corrector wheel

The corrector wheel is used in the neomatik caliber DUW 6101 for quick date adjustment. It allows the date to be adjusted in both directions (forward and backward) and prevents damage to the movement if an attempt is made to adjust the date manually during the short 90-minute locking period at midnight. Since the movement automatically switches to the next day at this point, manual correction is temporarily impossible. And if someone does try, the correction wheel gives way. Very clever! It has a slip clutch that engages at a certain force, allowing the gear driven by the crown to turn while the wheel remains stationary. The wheel and gear are riveted together with a friction spring. To ensure that the slip clutch does not engage too early or too late, everything must be perfectly coordinated, just like in a good team. We are happy to prove this and check every single correction wheel for the correct torque. Better safe than sorry!

6.10. Visual inspection of the minute markers

The dial of a watch is like a face—it has character. It is the part of the watch that attracts the most attention, that everyone likes to look at, and which also tells us the time. Always in harmony with the hands. That's why we check every dial to ensure it is flawless, that the fine lines of the minute track are correctly positioned, that the base color harmonizes with the hands, and that the precise time information is a visual delight. Practicality in its most beautiful form.

6.9. Testing the holding torque

The escape wheel, consisting of this single wheel and the escape wheel pinion, is riveted together at NOMOS Glashütte. The pinion receives power from the fourth wheel (which receives it from the mainspring), and the escape wheel transfers the power to the anchor. Of course, this only happens when the escape wheel and escape wheel pinion are firmly connected. At NOMOS, this is checked by trying to twist the wheel and pinion against each other—up to a defined force: the holding torque. Any actual twisting is immediately detected by the testing device. All wheels at NOMOS are checked this way. After all, only stable assembly processes lead to accuracy you can rely on.

6.8. Gauging straps

The strap of a NOMOS watch must, above all, be comfortable to wear. The focus here is on how it feels to the touch. Smooth leather or suede? Horween Genuine Shell Cordovan or vegan Alcantara? Textile or metal? NOMOS now offers a whole range of different straps and bracelets in various materials, colors, and finishes. They must also undergo strict incoming goods inspections—no strap is exempt. In addition to meeting visual criteria, the correct lug width is also checked. After all, the strap should neither be too tight nor too loose on the lugs of the case. To ensure this, the straps are subjected to a gauge test. The end piece of the strap is inserted into the first gauge. If it fits, the strap is not too wide. A second gauge checks whether the strap is too narrow; it must not fit into this gauge. Simple, fast, reliable. Quality in no time at all!

6.7. Fixing the ellipse

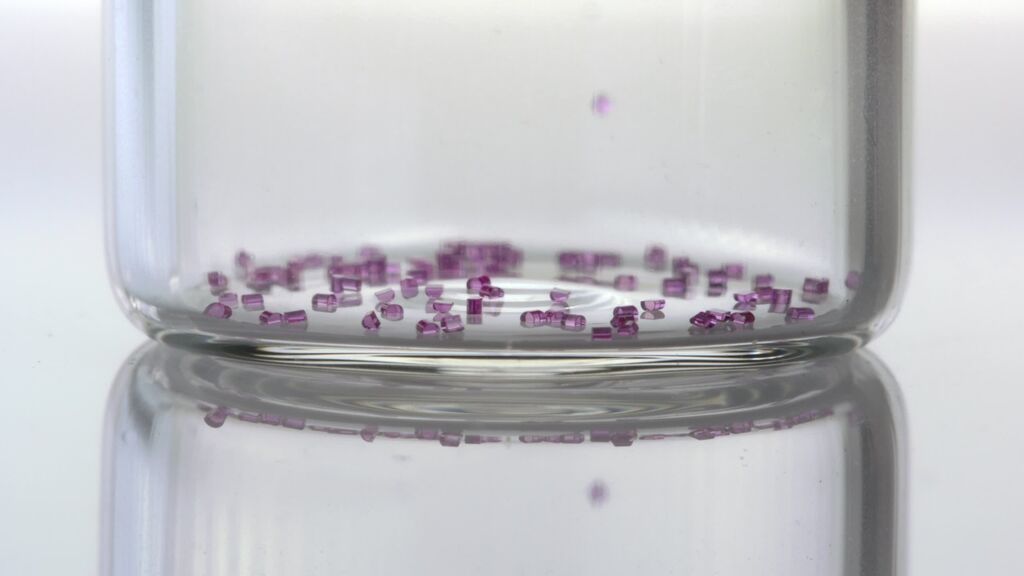

The ellipse, the balance wheel's lever stone, receives the drive impulse from the anchor and keeps the balance wheel swinging back and forth. Today, however, it resembles a half cylinder more than an ellipse. Its radius and length are significantly less than half a millimeter—tiny, yet so important. The ellipse is pressed into the plate, which is a delicate step in the manufacturing process. Even the slightest breeze can carry the tiny rubies away. That is why we use negative pressure when positioning the components. This ensures that everything stays where it belongs. After all, the ellipse has to transmit six impulses per second, which is 518,400 impulses per day, and almost 190 million per year. It is amazing what this tiny component can do!

6.6. Testing the water resistance

NOMOS watches with a whale engraved on the case back are safe to wear while swimming. NOMOS tests the water resistance of its watches using various methods. In individual testing, for example, the watch is subjected to a specific air pressure—which should lead to a minimal deformation of the case. If no changes can be detected, pressure equalization has taken place inside of the watch, meaning that it is not water resistant. When testing several watches at the same time, the volume method is used. Each watch is placed in its own chamber, which can only hold a certain volume of air. This is precisely defined in advance for each watch model. If more air fits in, it must be flowing into the watch. Not good. But since quality at NOMOS has nothing to do with luck, this is extremely rare. If a watch proves to be stubbornly leaky, we send it to the diving station, as shown here in the film. The leak is then revealed underwater.

6.5. Evenness test

NOMOS movements are distinguished not only by their precision, but also by their exceptional thinness. This does not happen by chance. In addition to innovative designs and special material properties, the material properties of the parts, such as thinness and evenness, are also very important. In our movements, space for each component is limited. This means that the distance between neighboring parts is not very large. As a result, the wheels cannot move far up or down when turning—watchmakers say that they must turn with particular evenness. That is why, at NOMOS, each wheel is checked for evenness after the individual parts have been assembled: visually, using a camera system, and with extreme precision. This is the only way NOMOS can achieve perfect function in such a small space.

6.4. Pressing in the anchor shaft

The anchor shaft is a very short shaft with even shorter pins. Its dimensions and surface finish must be perfect. This is because the anchor plays a central role in the NOMOS swing system. It converts the rotational movement of the anchor wheel into a back-and-forth movement, which gives the balance wheel an impulse with every contact. This is actually just a small push. But it involves the transfer of force combined with acceleration, taking inertia into account. Friction also plays a major role. So everything has to be perfect! The anchor shaft, pressed in at just the right height, ensures that the anchor is perfectly positioned between the anchor wheel and the balance wheel. Rolled pivots reduce friction in the bearing, and particularly tight tolerances keep the anchor as straight as possible. So the anchor shaft, as tiny as it is, has a pivotal role to play in the overall accuracy of a mechanical watch.

6.3. Quality assurance: tactile measurement

A tactile measuring method registers the contact of a body with a measuring tip. In other words, they get up close and personal. Modern optical measuring methods are very fast and very accurate. However, this is not always enough when it comes to manufacturing watch movements. Due to a wide range of influences—such as light, surface texture and reflections—the measuring accuracy of optical methods decreases in some cases. This is where tactile processes have the advantage. Whether inner or outer diameter, heights or entire contours, manual or fully automatic, almost anything is possible—if you know how. Only qualified technicians like those at NOMOS Glashütte know how to use the various measurement methods correctly.

6.2. Adjusting the end of the balance spring

The last, curved part of the balance spring is known as the end curve. In the past, there was even an inner end curve. The end curve is used to attach it to the stud holder, and thus to the balance cock. In addition, the end curve is often used to quickly adjust the pace of the watch, because the frequency—which is the oscillation of the balance wheel—can be influenced by changing the effective length of the balance spring. To ensure that this happens reliably and in even steps, the end curve must have a perfect radius to the center point. This requires a keen eye, a steady hand, and a great deal of experience.

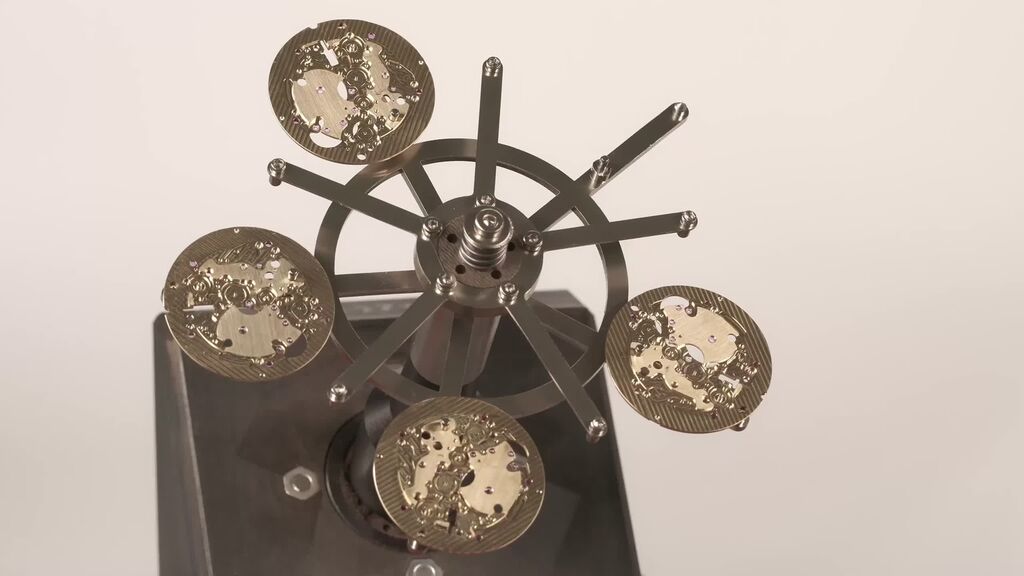

6.1. Sandblasting

Almost all of the framing movement parts at NOMOS are allowed to ride this carousel without having to queue: movement plates, three-quarter plates, balance cocks, and bridges. While they do, the parts also get a good sandblasting. But in a very gentle way—because it's not sand, but the finest bronze filings. This evens out the many different surface structures that result from the machining process. Not only does it look better, this also helps with optical measurement methods, creates an even surface for polishing, and smoothes some of the edges. And it's fascinating to watch!