Have you ever watched the hands of your timepiece tick around the dial and wondered how it all works? We can explain.

To start at the beginning: All movements require an energy source to function. With automatic and manual movements, which are what you will find within NOMOS watches, you, the wearer, are the energy source. To power a manual watch, you have to wind it yourself—and after just a few turns of the crown the balance will start to move. When you feel a strong resistance, this means that the mainspring is fully wound. In contrast, for automatic watches: A bit of movement from the arm is enough to give a watch all the energy it needs—simply by stirring your soup, watering your flowers, or occasionally doing the vacuuming. As soon as the movement receives its first lot of energy, it will care of the rest itself—automatically. But both types of caliber need somewhere to store this kinetic energy as well as hands to be moved and a regulation system to ensure that the hands do not move too fast or too slowly.

The rotor is being set: It provides automatic movements with all the swing they need, transforming motion into time.

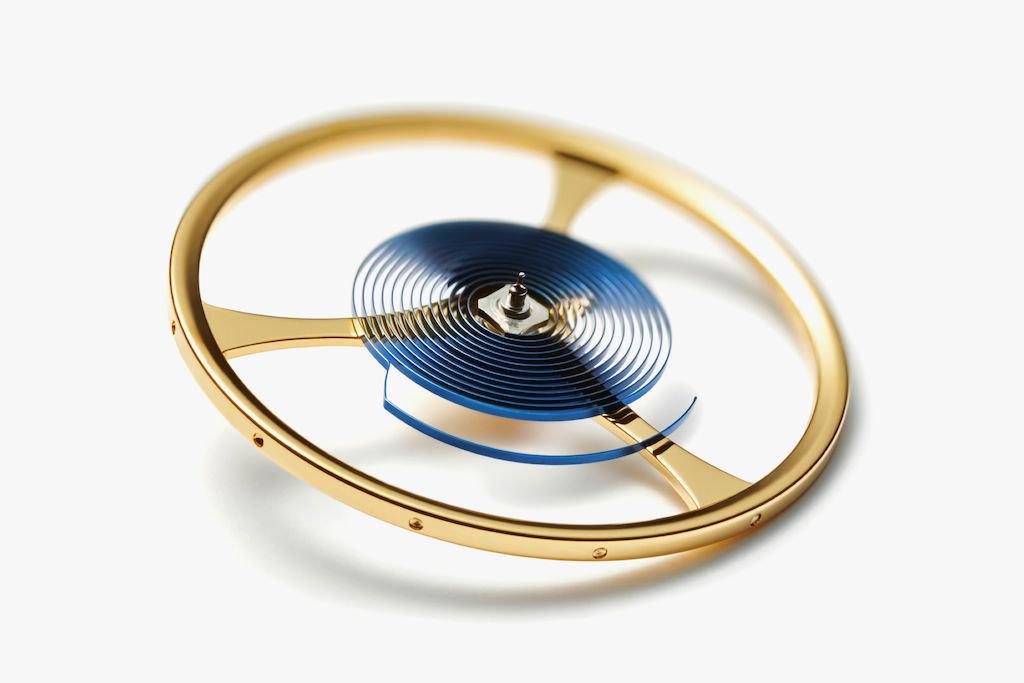

The escapement is the pacesetting component of a watch movement. A tiny assembly of parts, comprising the balance wheel, balance spring, pallet, and escape wheel—together, they form the heart of every mechanical watch. The wound-up mainspring stores its energy in the barrel, from where it is transmitted via the three gear wheels (the center, third, and fourth wheel) to the escape wheel, and the pallet receives an impulse. The long end of the pallet then relays this impulse to the ellipse of the balance wheel, which rotates and stretches the balance spring—although only as far as the energy of the impulse suffices. Then the balance wheel swings back and the energy now flows the other way. This toing-and-froing creates a swinging motion, which gives the NOMOS swing system—the watchmaking company’s proprietary escapement—its name. Producing this component in-house and independently is a technical sensation and rarity in the world of fine watchmaking—NOMOS Glashütte, after years of research and investment, has mastered this art.

The escapement is also responsible for the tick and tock of the watch—or more specifically the escape wheel, which is designed with asymmetric teeth. It isn’t constantly rotating in the caliber, but rather in a stop-and-start motion (thanks to the catch and release of the pallet fork). Each movement creates a tick. This means that the escapement pauses for a moment with every tick and tock, before moving the hands of the watch a tiny bit further.

The shape of the teeth on the escape wheel enable them to catch both ends of the pallet in turns.

The pallet is loaded with two fine blade-shaped jewels. These tiny parts latch onto the teeth of the escape wheel.

Thanks to the balance wheel—here with the blue NOMOS balance spring—the mainspring can release its energy in regulated bursts, rather than all at once.

The process that takes place within the escapement repeats again and again: The oscillation frequency of a watch is 3 hertz, so six half-swings per second (i.e. the watch is stopped by the escapement six times a second). The balance of NOMOS watches swings back and forth 21,600 times an hour, 518,400 times a day, dividing up the time. Ultimately, the accuracy of a watch depends mostly on how well the regulation system can keep the pauses an equal length, before releasing the energy from the mainspring a tiny bit at a time to the hands. You could also say: Measuring time means counting the pauses.

Time in its most beautiful form: The neomatik date caliber DUW 6101, visible through the sapphire crystal glass of the self-winding award-winner from NOMOS, Tangente Update.

Once all the tension has been released, it’s time to rewind the watch. In NOMOS timepieces, this is usually after 43 hours—or 42 hours if the caliber features an additional complication. That’s because a watch needs a bit more energy to change the date, of course, before continuing to tick reliably and precisely once more—with enough energy, 100 million times a year.

PUBLICATION DATE: September 2019

TEXT: NOMOS Glashütte

IMAGES: 1.–6. NOMOS Glashütte/Holger Wens